Pipe Wall Thickness Calculations

Calculating the wall thickness of a pipe is essential for ensuring the structural integrity and safety of piping systems, especially under internal pressure. The following steps outline how to calculate the pipe wall thickness based on ASME standards, particularly ASME B31.3 for process piping.

Steps for Pipe Wall Thickness Calculations Based on ASME

1. Determine Design Parameters

- Internal Design Pressure (P): The maximum internal pressure the pipe will experience (measured in psi or Pa).

- External Pressure (Pe): If applicable, the external pressure impacting the pipe (measured in psi or Pa).

- Design Temperature (T): The maximum temperature the pipe will operate at (°C or °F).

- Pipe Diameter (D): The nominal outside diameter of the pipe (in inches or mm).

2. Identify Material Properties

- Allowable Stress (S): Obtain the allowable stress of the material at the design temperature, which can be found in ASME Section II, Material Specifications, or the material’s datasheet (measured in psi or Pa).

- Thickness Corrosion Allowance: Account for any additional thickness required for corrosion or erosion, usually expressed as a fixed value (in inches or mm).

3. Select the appropriate ASME formula

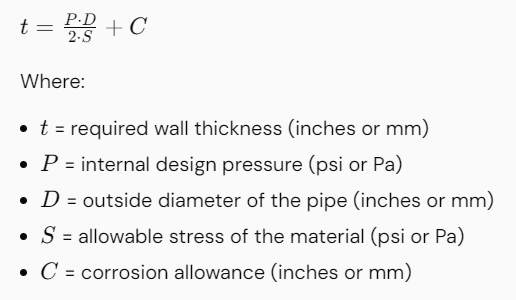

For an internally pressurized pipe, the minimum required thickness can be calculated using the following formula from ASME B31.3:

Note: For specified thickness definitions within ASME, you may also include a term for the minimum wall thickness. This can be specifically stated in different ASME sections.

4. Account for External Pressure (if applicable)

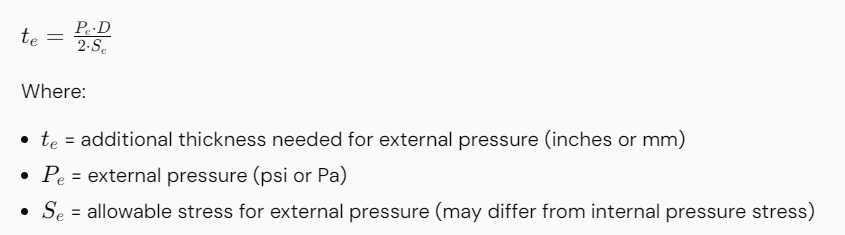

If the pipe is subject to external pressure, you must also consider the external pressure when calculating the wall thickness. Use the formula:

5. Determine the Design Thickness

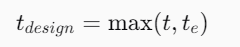

Combine thicknesses computed for internal and external pressures:

This equation helps in determining the final design thickness, accounting for both internal and external pressures.

6. Check Against Standard Pipe Schedules

Check if the calculated wall thickness meets or exceeds available standard pipe sizes and schedules (such as Schedule 40, 80). Pipe thicknesses defined by ASME pipe schedule can be found in ASME B36.10 and ASME B36.19.

7. Consider Additional Design Factors

Include any additional factors such as:

- Fatigue considerations for cyclic loading.

- Impact considerations for low-temperature applications.

Adjust the thickness accordingly if required by safety factors or specific application standards.

8. Final Review and Compliance Verification

Ensure the final design meets all relevant codes and standards (such as ASME B31.3, B31.1, etc.) and industry best practices. Perform peer reviews or checks per organizational procedures.

Summary

Calculating pipe wall thickness using ASME standards requires a comprehensive understanding of the operational conditions, material properties, and appropriate mathematical formulas. Consider the internal and external pressures, allowable stress, and corrosion allowances to ensure safety and compliance. This process is critical for the design, material selection, fabrication, and maintenance planning of piping systems. Always refer to the latest ASME codes and standards for the most accurate and safe design practices.