How to Perform Stress Analysis Calculations for Pipelines

Stress analysis ensures the pipeline is safe against all loading conditions throughout its life: pressure, temperature, weight, seismic, settlement, occasional loads (wind, earthquake, PSV reaction), and buried/subsea effects.

1. When Is Stress Analysis Required?

| Case | Mandatory? | Code/Reference |

|---|---|---|

| ASME B31.3 (Process Piping) | Yes if high T or large ΔT | B31.3 §301.4 |

| ASME B31.4 (Liquid Pipelines) | Yes for all above-ground & critical buried | B31.4 §401.5 |

| ASME B31.8 (Gas Pipelines) | Yes for compressor stations, above-ground spans | B31.8 §833 |

| ASME B31.8S + API 579 | Flexibility + Fitness-for-Service | |

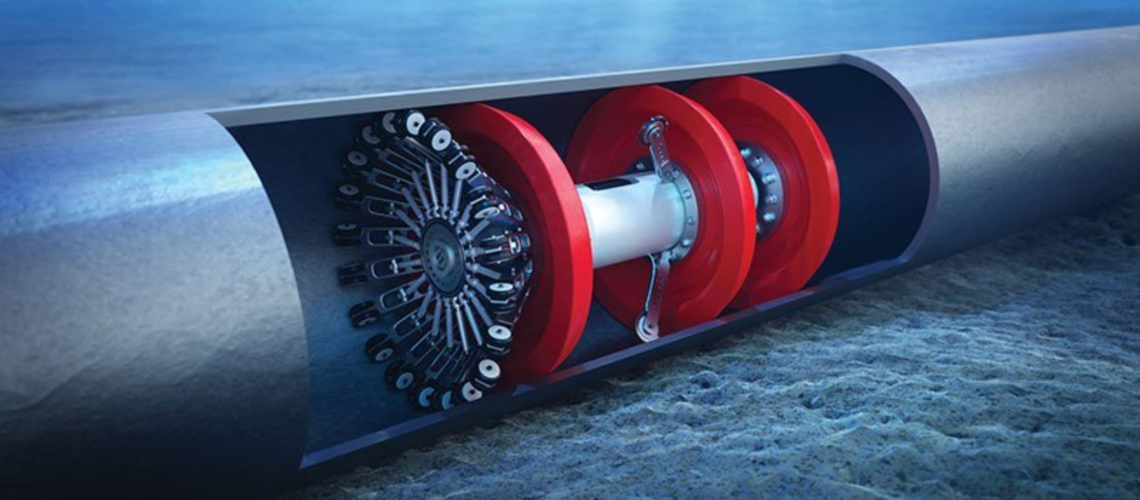

| DNV-OS-F101 / ISO 13628 | Subsea pipelines & risers | |

| Buried pipelines > DN400 or ΔT > 50°C | Usually required (causes longitudinal stress) |

2. Types of Stress Analysis

| Type | What It Checks | Code Limits |

|---|---|---|

| Flexibility Analysis | Sustained + Expansion (thermal, settlement) | B31.3, B31.4, B31.8 |

| Occasional Analysis | Sustained + Wind/Earthquake/PSV | < 1.33 × Sh or 1.5 × Sh |

| Fatigue Analysis | Cyclic thermal or pressure (especially risers) | SN curves (DNV, API) |

| Buckling / Collapse | Buried (traffic) or subsea (external pressure) | DNV-OS-F101, API 1111 |

| Fracture Mechanics | Crack-like defects | BS 7910, API 579 |

3. Step-by-Step Calculation Procedure (ASME B31.3 Example)

Step 1 – Define Load Cases (B31.3 Table 320.1)

| Load Case | Combination | Purpose |

|---|---|---|

| Sustained | W + P (internal pressure + weight) | Hoop + longitudinal stress |

| Expansion | T1 – T2 (thermal expansion) | Flexibility stress range |

| Occasional | W + P + Wind or Earthquake or PSV | Allowable 1.33 Sh |

| Operating | W + P + T | Displacement check |

Step 2 – Calculate Primary Stresses (Pressure + Weight)

Hoop stress (always checked):

σ_h = P × (D₀ – t) / (2t) ≤ Sh

Longitudinal sustained:

σ_L = P × D / (4t) + M_z / Z (bending from weight) ≤ Sh

Step 3 – Calculate Thermal Expansion Stress Range (Secondary)

Displacement stress range SE:

SE = √[ (ii × Mi)² + (io × Mo)² + 4 × Mt² ] / Z ≤ SA

Where:

- SA = f (1.25 Sc + 0.25 Sh) (f = cycle factor)

- ii, io = in-plane & out-plane stress intensification factors (B31.3 Appendix D)

Step 4 – Software Workflow

| Software | Best For | License 2025 |

|---|---|---|

| CAESAR II (Hexagon) | #1 for ASME B31.3, B31.4, B31.8, EN 13480 | $$$ |

| AutoPIPE (Bentley) | Nuclear, buried, seismic, jacketing | $$$ |

| ROHR2 (Sigma) | Europe (EN 13480), very good buried analysis | $$ |

| START-PROF | Cheapest professional, excellent buried | $ |

| PASS/START (NTI) | Russian GOST + ASME | $ |

| SIMFLEX-II | Quick screening | Free–$ |

Step 5 – Typical CAESAR II Modeling Steps

- Input pipe properties (D, t, material, insulation, fluid)

- Define temperature & pressure cases

- Add supports/restraints:

- +Y (vertical support)

- Anchors, guides, rests, springs, expansion joints

- Add occasional loads (wind per ASCE 7-22 or EN 1991, earthquake per IBC/ASCE 7 or EN 1998)

- Run static load cases (SUS, EXP, OCC)

- Check code compliance report:

- Sustained ≤ Sh

- Expansion ≤ SA

- Occasional ≤ 1.33 Sh

- Restraint loads

- Nozzle loads on pumps/compressors (API 610/617 limits)

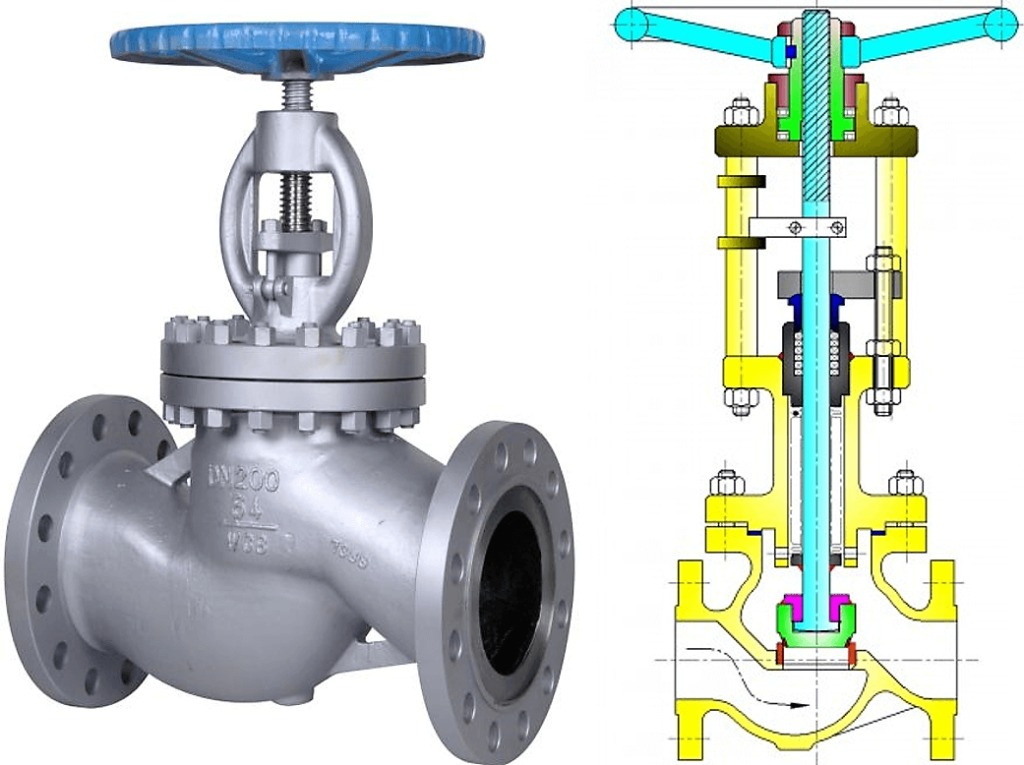

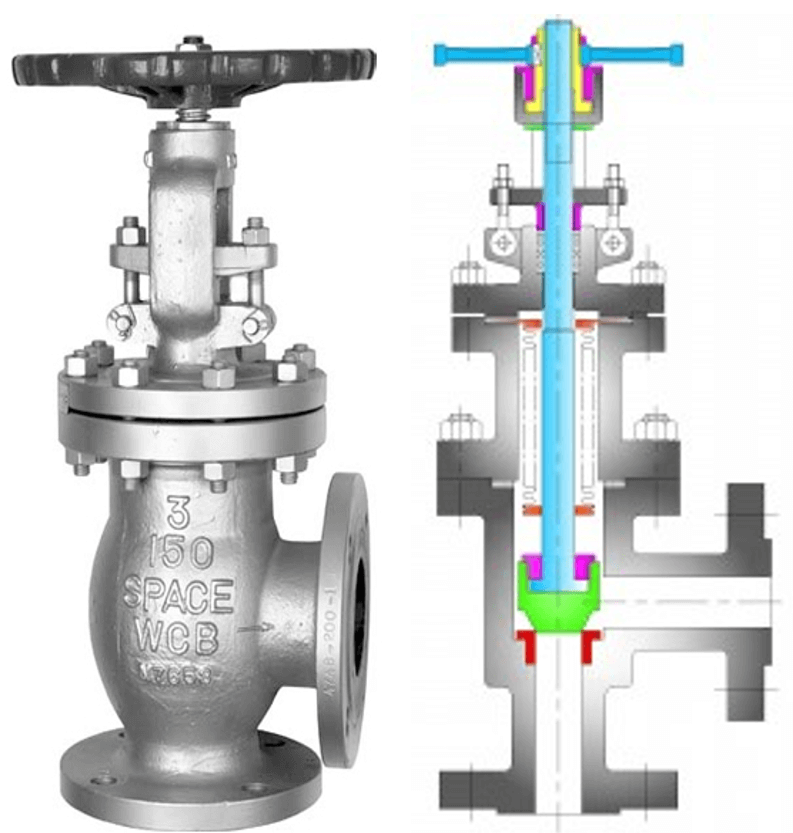

- Flange leakage check (ASME VIII Div.1 App.2 or EN 1591)

Step 6 – Buried Pipeline Special Cases (ASME B31.4 / B31.8)

Longitudinal stress from temperature + Poisson:

σ_L = E α ΔT – ν σ_h + bending from soil settlement

Use CAESAR II or START-PROF buried module with:

- Soil spring stiffness (ALA 2005 or EN 1998-4)

- Virtual anchor length calculation

- Maximum span between soil anchors

Step 7 – Quick Hand Calculation Example (Simple Case)

10” Sch40 carbon steel pipeline, 200 m straight run between two anchors, ΔT = 80°C, buried.

- Material A106 Gr.B → E = 203 GPa, α = 12×10⁻⁶ /°C

- Hoop stress σ_h = 90 bar × (273-8.18)/(2×8.18) ≈ 115 MPa

- Fully restrained → σ_L = E α ΔT – ν σ_h

= 203×10⁹ × 12×10⁻⁶ × 80 – 0.3 × 115×10⁶

= 194.9 – 34.5 = 160 MPa (compressive)

Allowable compressive stress ≈ 0.9 Fy = 0.9×245 = 220 MPa → OK

But you need expansion loops every ~150–300 m depending on diameter.

4. Rules of Thumb

| Parameter | Typical Limit / Rule |

|---|---|

| Max thermal stress range | < 200 MPa for CS, < 150 MPa for SS |

| Expansion loop leg length | ≈ 10 × √(D × ΔT) in meters (D in mm) |

| Allowable nozzle load | API 610 pump: 6–10 × NEMA forces |

| Minimum straight run before bend | 5–10 × D to avoid SIF errors |

| Guide spacing (above ground) | 15–25 m for DN ≤ 12”, 25–40 m for larger |

| Buried soil stiffness | Vertical 20–50 N/cm³, axial 0.5–2 N/cm³ |

5. Deliverables of a Proper Stress Analysis Report

- Critical line list

- Isometric markups with support locations

- CAESAR II input files (.c2)

- Code compliance tables (sustained, expansion, occasional)

- Restraint load summary

- Spring hanger table

- Flange leakage report

- Expansion joint or bellows datasheet

- Recommendations (add loops, change support type, etc.)

If you send me a specific line (diameter, temperature, pressure, routing sketch, support types), I can give you the exact loop size, support spacing, or run a quick CAESAR II calculation and send the results.