I. Purpose

- To ensure that all piping materials received at the job site conform to the specified requirements of the project and ASME B31.3

- To establish a system for verifying material identity, quality, and documentation

- To prevent the use of non-conforming materials in the piping system

II. Scope

This procedure applies to all piping materials, including pipes, fittings, flanges, valves, gaskets, bolts, and other components used in the construction of piping systems

III. References

- ASME B31.3, Process Piping

- ASME Section II, Materials

- Project Piping Material Specification

- Approved Piping Drawings and Material Take-Offs (MTOs)

- Purchase Orders

- ASTM Standards (as applicable to specific materials)

- Company Quality Control Manual

IV. Responsibilities

- Procurement Department: Responsible for ensuring that purchase orders accurately reflect the project’s material requirements

- Receiving Inspector: Responsible for performing the receiving inspection in accordance with this procedure

- Quality Control (QC) Engineer: Responsible for overseeing the receiving inspection process and resolving any non-conformance issues

- Material Controller: Responsible for maintaining material traceability and storage

V. Procedure

A. Pre-Receiving Activities

- 1. Review Documentation: Before material arrives, the Receiving Inspector shall review the Purchase Order, Material Requisition, Piping Material Specification, and approved drawings to understand the material

- 2. Prepare Inspection Area: Ensure a designated receiving area is available with adequate lighting, measuring tools, and access to relevant specifications

- 3. Obtain Approved Vendor List: Verify that the material supplier is an approved vendor per the project’s quality control requirements.

B. Receiving Inspection Steps

1. Visual Inspection:

- Verify Packing List: Check the packing list against the purchase order to confirm the correct quantity and description of materials received

- Inspect for Damage: Carefully examine all materials for any signs of damage during shipping, such as dents, bends, corrosion, or broken packaging.

- Document any damage on the receiving report and notify the supplier

- Check for Proper Marking: Verify that each item is clearly and legibly marked with the correct material grade, size, schedule, and heat number.

- Markings should comply with applicable standards (e.g., ASME, ASTM)

2. Material Verification:

- Review Material Test Reports (MTRs): Obtain and review the MTRs (also known as Certified Material Test Reports or CMTRs) for each material lot

- Compare MTRs to Specifications: Verify that the chemical composition, mechanical properties (tensile strength, yield strength, elongation), and heat treatment listed on the MTRs meet the requirements of the applicable material specification (e.g., ASTM A106 Grade B, ASTM A105) and the project piping material specification

- Verify Traceability: Ensure that the heat number on the MTR matches the heat number marked on the material

- This confirms traceability of the material back to its origin

- Positive Material Identification (PMI): For critical applications or materials susceptible to mix-ups (e.g., alloy steels), perform PMI using a portable spectrometer to verify the material’s chemical Document PMI results

3. Dimensional Verification:

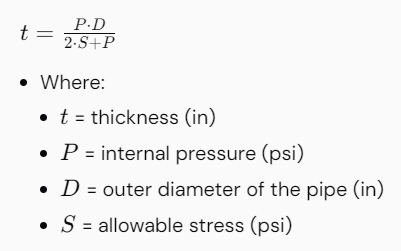

- Check Dimensions: Using calibrated measuring tools (e.g., calipers, tape measure), verify that the dimensions of the received materials (pipe diameter, wall thickness, flange dimensions, fitting dimensions) conform to the specified standards and the project drawings

- Verify Wall Thickness: Use ultrasonic thickness testing to verify the wall thickness of pipes and fittings, especially for corrosion-resistant alloys.

4. Specific Component Checks:

- Pipes: Check for straightness, ovality, and surface defects

- Fittings: Verify the angle, radius, and end preparation (e.g., bevel angle for welding

- Flanges: Check flange face finish, bolt hole alignment, and dimensions

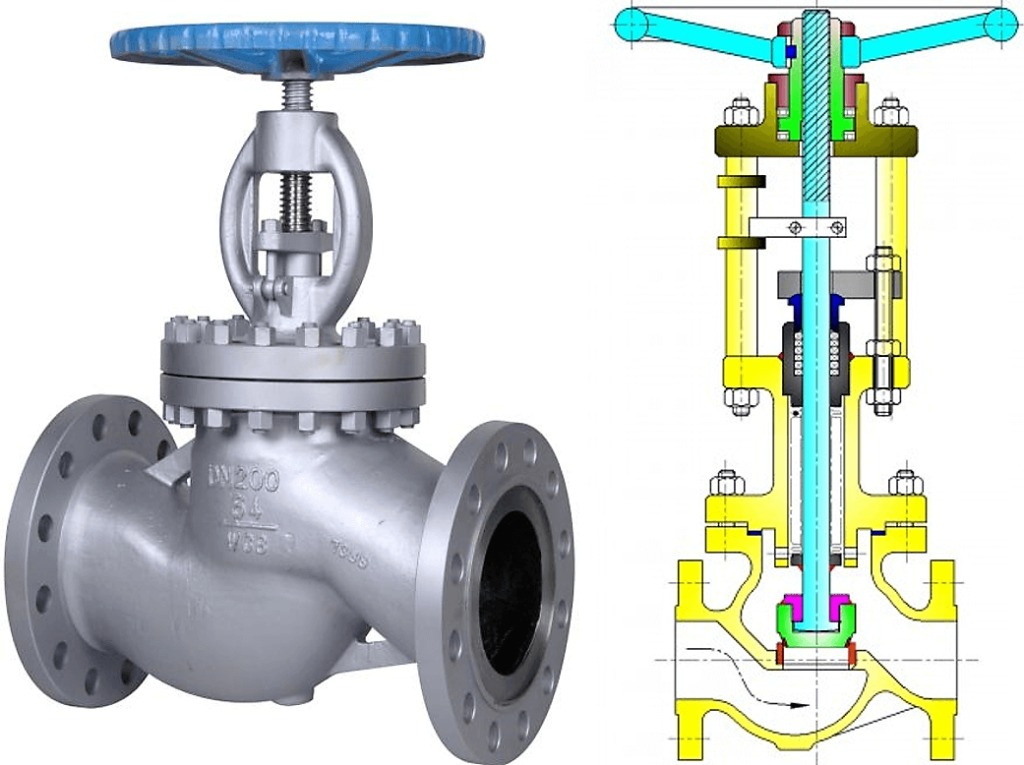

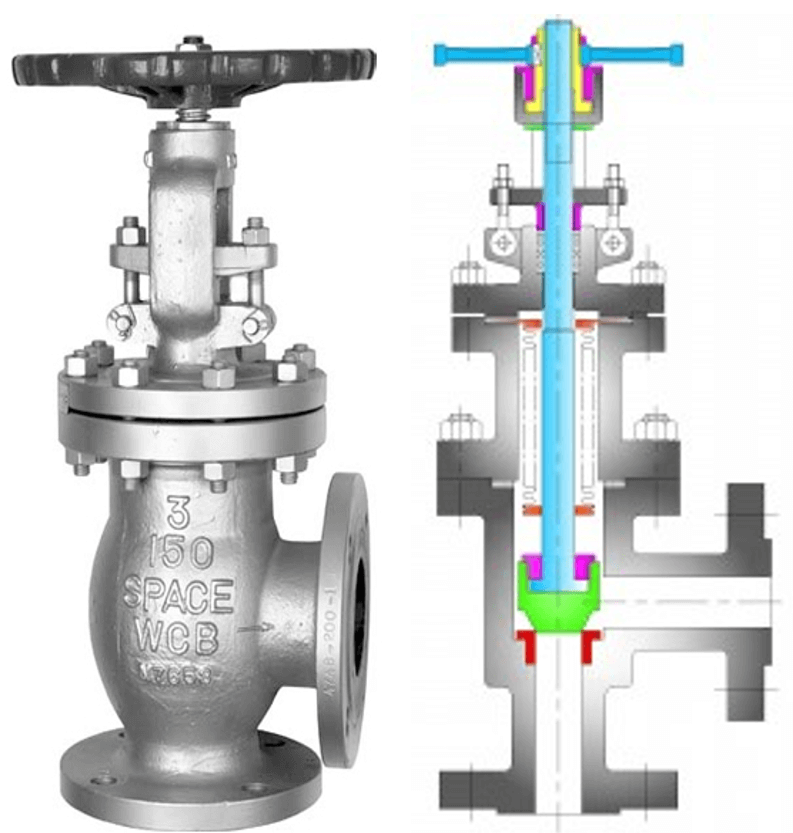

- Valves: Verify valve type, pressure rating, end connections, and operator type. Check for smooth valve operation

- Bolting: Verify bolt diameter, length, material grade, and thread

- Gaskets: Check gasket type, size, and material compatibility with the intended

5. Documentation:

- Complete Receiving Inspection Report: Document all inspection results on a receiving inspection report, including the purchase order number, material description, quantity inspected, inspection date, inspector’s name, and any discrepancies or non-conformances

- Attach MTRs: Attach copies of the MTRs to the receiving inspection

- Maintain Records: Maintain a file of all receiving inspection reports, MTRs, and related documentation for future

C. Non-Conformance Handling

- 1. Identify Non-Conformances: Any material that does not meet the specified requirements shall be identified as non-conforming

- 2. Segregation: Segregate non-conforming materials from conforming materials to prevent accidental use

- 3. Notification: Notify the QC Engineer and Procurement Department of the non-conformance

- 4. Disposition: The QC Engineer will determine the appropriate disposition of the non-conforming material, which may include:

- Return to Supplier: Return the material to the supplier for replacement or credit

- Repair: Repair the material, if possible, and re-inspect to verify conformance

- Use-as-is: Accept the material “as-is” with a deviation, if it is determined that the non-conformance does not affect the safety or functionality of the piping system. This requires approval from the Engineering Department and the client, if

- 5. Documentation: Document the non-conformance and the resolution on a Non-Conformance Report (NCR)

D. Material Storage and Handling

- Proper Storage: Store materials in a clean, dry, and secure area to prevent damage or deterioration

- Material Identification: Maintain material identification throughout storage and handling

- Handling Procedures: Use proper lifting and handling equipment to prevent damage to materials

- Inventory Control: Implement an inventory control system to track the location and status of all piping materials

VI. Acceptance Criteria

- Materials are accepted if they meet all the requirements of this procedure, the applicable material specifications, and the project piping material

- All documentation is complete and accurate

- There are no unresolved non-conformances

VII. Training

All personnel involved in the receiving inspection process shall be trained on this procedure and the relevant material specifications

VIII. Records

- Receiving Inspection Reports

- Material Test Reports (MTRs)

- Non-Conformance Reports (NCRs)

- Purchase Orders

- Material Requisitions

- Calibration Records for Measuring Equipment

- PMI Reports

This comprehensive procedure ensures that all piping materials are thoroughly inspected upon arrival at the job site, minimizing the risk of using non-conforming materials and ensuring the integrity of the piping system

Remember to adapt this procedure to your specific project requirements and company standards.