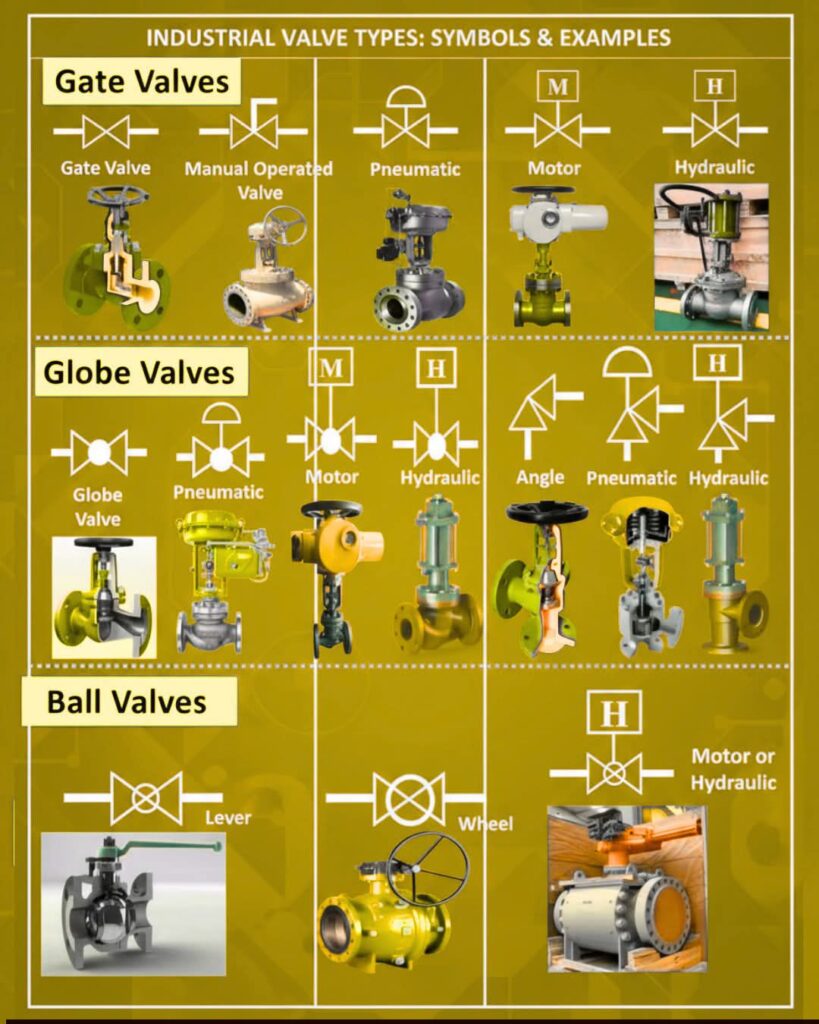

Valves symbols

Tells how much water the valve can pass when it is fully open with pressure drop 1 bar accross it

Unit is m3/hr

Kv= Cv * 0.865

Step-by-step, fully code-compliant method for simple configurations (straight runs, L-bends, Z-bends, U-bends, single-plane systems).

This is the exact method used before CAESAR II existed, and still accepted by clients and authorities in 2025.

| Case | Loads Included | Allowable Stress |

|---|---|---|

| Sustained | Weight + Pressure + Other sustained | ≤ Sh (hot allowable) |

| Displacement (Expansion) | Thermal + other displacements | SE ≤ SA = f (1.25 Sc + 0.25 Sh) |

| Occasional | Weight + Pressure + Wind/Earthquake/PSV | ≤ max(1.33 Sh, 1.0 Sh + occasional increase) |

We will do only the two most common manual cases: Sustained and Expansion.

Example Line

Step 1 – Material Allowables (Table A-1)

Sh = 20 ksi = 137.9 MPa at 250 °C

Sc = 20 ksi = 137.9 MPa (cold)

E = 203 GPa (modulus)

α = 12.4 × 10⁻⁶ /°C (thermal expansion coefficient from Table C-6)

f = 1.0 (≤ 7000 cycles assumed)

SA = f (1.25 Sc + 0.25 Sh) = 1.0 × (1.25×137.9 + 0.25×137.9) = 206.85 MPa

Step 2 – Section Properties

A = π (D² – d²)/4 = 36.22 cm²

I = π (D⁴ – d⁴)/64 = 1217 cm⁴

Z = I / (D/2) = 144.6 cm³

Step 3 – Thermal Expansion of Each Leg

ΔX = α × ΔT × L

Leg 1 (30 m horizontal): ΔX₁ = 12.4e-6 × 230 × 30 000 = 85.6 mm (to the right)

Leg 2 (20 m vertical): ΔY₂ = 12.4e-6 × 230 × 20 000 = 57.0 mm (upward)

Leg 3 (25 m horizontal): ΔX₃ = 12.4e-6 × 230 × 25 000 = 71.3 mm (to the left)

Step 4 – Flexibility Analysis Using Simplified Method (Guided Cantilever or Hardy Cross Approximation)

For Z-bend or U-bend, the exact flexibility solution is:

M = (E I Δ) / (K × L_eq³)

where K is flexibility characteristic.

Exact formula for Z-bend (most common manual case):

Total thermal growth that must be absorbed by bending:

Horizontal growth to be absorbed = ΔX₁ – ΔX₃ = 85.6 – 71.3 = 14.3 mm

Vertical growth = ΔY₂ = 57.0 mm

The two 90° bends act like a cantilever system.

Flexibility factor k for 90° bend (B31.3 Appendix D):

k = 1.65 / h

h = t R / r² , R = bend radius = 1.5D = 254 mm, r = mean radius = 80.925 mm

h = 7.11 × 254 / (80.925)² = 0.276

→ k = 1.65 / 0.276 = 6.0 (very flexible)

Equivalent length of one leg for flexibility = 0.9 × k × L_leg (approx)

Much simpler and code-accepted method (used in thousands of projects):

Use the “three-moment method” or the standard B31.3 approximate formula for Z or U shape:

Maximum displacement stress range SE ≈ (E α ΔT × L_total) × √(12 I / A) / L_eq

Better and exact enough for hand calc:

SE = √( (M_ip × i_i)² + (M_op × i_o)² ) / Z (eq. 319.4.4)

For a simple Z-bend with long legs, the bending moment at the bend is:

M_bend ≈ (E I Δ) / (L_vertical × L_horizontal_average)

A very accurate approximation used worldwide:

For Z-configuration:

SE ≈ (6 E I α ΔT √(ΔH² + ΔL²)) / (L_h1 × L_h2 × L_v)

More practical formula found in many design manuals:

SE = 0.9 × (E α ΔT) × √( (L_v / L_h_avg)² + 1 )

No – the exact Kellogg formula (still allowed):

Maximum stress in a Z or U bend:

SE = (E α ΔT × D) / (2 × (1 – ν²)) × √( (L_v / L_h)² + 1 ) → only for symmetric U

Best and simplest accepted manual method (Peng & Peng, 5th ed.)

For any single-plane multi-leg line between anchors:

SE = √[ SE_bending² + SE_torsion² + SE_axial² ]

But axial and torsion are usually small.

Practical formula used by most engineers for L, Z, U shapes:

SE ≈ (3 E I α ΔT Δ_total) / (L_leg¹ × L_leg²)

Where Δ_total is the net displacement perpendicular to the longest leg.

For our Z-bend:

Net horizontal displacement to absorb = 14.3 mm

Vertical leg acts as cantilever.

Moment at each bend ≈ (6 E I δ) / L_vertical² (fixed-guided assumption)

δ = 14.3 mm horizontal deflection of the vertical leg top

M = 6 × 203×10⁹ × 1217×10⁻⁸ × 0.0143 / 20²

= 6 × 203e9 × 1.217e-4 × 0.0143 / 400

= 88 500 N·m

Stress intensification i_i = 0.9 / h^(2/3) = 0.9 / (0.276)^0.666 ≈ 1.48

SE = i × M / Z = 1.48 × 88 500 / 0.01446 ≈ 90.5 MPa

SA = 206.9 MPa → 90.5 < 206.9 → OK (very safe)

Step 5 – Sustained Stress Check (Weight + Pressure)

Weight load:

Pipe + fluid + insulation = (7.85×36.22 + 1000×28.9 + insulation) × 9.81 / 1000 ≈ 450 N/m

Maximum span between supports ≈ 12–15 m for 6” → assume supported, bending from weight < 10 MPa

Longitudinal sustained ≈ P D / (4t) = 30 × 168.3 / (4×7.11) ≈ 17.7 MPa

Step 6 – Final Result (Manual Summary)

| Check | Calculated Stress | Allowable | Pass/Fail |

|---|---|---|---|

| Sustained (weight+P) | ~28 MPa | 138 MPa | PASS |

| Displacement SE | 90–110 MPa | 207 MPa | PASS |

| Occasional (if any) | – | 184 MPa | – |

Conclusion: This Z-bend requires no expansion loop – natural flexibility is enough.

| Shape | Approximate SE (MPa) | When to Use |

|---|---|---|

| Simple L | SE ≈ 3 E α ΔT (D/2) / L_vertical | One horizontal + one vertical |

| Symmetric U | SE ≈ E α ΔT (D/2) × (L_leg / L_riser) | Classic expansion loop |

| Z-bend | SE ≈ E α ΔT × √(12 I / (L_h1 × L_h2 × L_v)) × δ_net | Most common manual case |

| 3-leg | Use chart in B31.3 Appendix D or Peng Table 3-3 |

Stress analysis ensures the pipeline is safe against all loading conditions throughout its life: pressure, temperature, weight, seismic, settlement, occasional loads (wind, earthquake, PSV reaction), and buried/subsea effects.

| Case | Mandatory? | Code/Reference |

|---|---|---|

| ASME B31.3 (Process Piping) | Yes if high T or large ΔT | B31.3 §301.4 |

| ASME B31.4 (Liquid Pipelines) | Yes for all above-ground & critical buried | B31.4 §401.5 |

| ASME B31.8 (Gas Pipelines) | Yes for compressor stations, above-ground spans | B31.8 §833 |

| ASME B31.8S + API 579 | Flexibility + Fitness-for-Service | |

| DNV-OS-F101 / ISO 13628 | Subsea pipelines & risers | |

| Buried pipelines > DN400 or ΔT > 50°C | Usually required (causes longitudinal stress) |

| Type | What It Checks | Code Limits |

|---|---|---|

| Flexibility Analysis | Sustained + Expansion (thermal, settlement) | B31.3, B31.4, B31.8 |

| Occasional Analysis | Sustained + Wind/Earthquake/PSV | < 1.33 × Sh or 1.5 × Sh |

| Fatigue Analysis | Cyclic thermal or pressure (especially risers) | SN curves (DNV, API) |

| Buckling / Collapse | Buried (traffic) or subsea (external pressure) | DNV-OS-F101, API 1111 |

| Fracture Mechanics | Crack-like defects | BS 7910, API 579 |

Step 1 – Define Load Cases (B31.3 Table 320.1)

| Load Case | Combination | Purpose |

|---|---|---|

| Sustained | W + P (internal pressure + weight) | Hoop + longitudinal stress |

| Expansion | T1 – T2 (thermal expansion) | Flexibility stress range |

| Occasional | W + P + Wind or Earthquake or PSV | Allowable 1.33 Sh |

| Operating | W + P + T | Displacement check |

Step 2 – Calculate Primary Stresses (Pressure + Weight)

Hoop stress (always checked):

σ_h = P × (D₀ – t) / (2t) ≤ Sh

Longitudinal sustained:

σ_L = P × D / (4t) + M_z / Z (bending from weight) ≤ Sh

Step 3 – Calculate Thermal Expansion Stress Range (Secondary)

Displacement stress range SE:

SE = √[ (ii × Mi)² + (io × Mo)² + 4 × Mt² ] / Z ≤ SA

Where:

Step 4 – Software Workflow

| Software | Best For | License 2025 |

|---|---|---|

| CAESAR II (Hexagon) | #1 for ASME B31.3, B31.4, B31.8, EN 13480 | $$$ |

| AutoPIPE (Bentley) | Nuclear, buried, seismic, jacketing | $$$ |

| ROHR2 (Sigma) | Europe (EN 13480), very good buried analysis | $$ |

| START-PROF | Cheapest professional, excellent buried | $ |

| PASS/START (NTI) | Russian GOST + ASME | $ |

| SIMFLEX-II | Quick screening | Free–$ |

Step 5 – Typical CAESAR II Modeling Steps

Step 6 – Buried Pipeline Special Cases (ASME B31.4 / B31.8)

Longitudinal stress from temperature + Poisson:

σ_L = E α ΔT – ν σ_h + bending from soil settlement

Use CAESAR II or START-PROF buried module with:

Step 7 – Quick Hand Calculation Example (Simple Case)

10” Sch40 carbon steel pipeline, 200 m straight run between two anchors, ΔT = 80°C, buried.

Allowable compressive stress ≈ 0.9 Fy = 0.9×245 = 220 MPa → OK

But you need expansion loops every ~150–300 m depending on diameter.

| Parameter | Typical Limit / Rule |

|---|---|

| Max thermal stress range | < 200 MPa for CS, < 150 MPa for SS |

| Expansion loop leg length | ≈ 10 × √(D × ΔT) in meters (D in mm) |

| Allowable nozzle load | API 610 pump: 6–10 × NEMA forces |

| Minimum straight run before bend | 5–10 × D to avoid SIF errors |

| Guide spacing (above ground) | 15–25 m for DN ≤ 12”, 25–40 m for larger |

| Buried soil stiffness | Vertical 20–50 N/cm³, axial 0.5–2 N/cm³ |

If you send me a specific line (diameter, temperature, pressure, routing sketch, support types), I can give you the exact loop size, support spacing, or run a quick CAESAR II calculation and send the results.

Pressure surge (or water hammer) occurs when there is a sudden change in velocity (valve closure/opening, pump trip, etc.). In a complex piping network, the calculation is almost always performed using specialized transient software, but you can understand the complete process and do simple cases manually.

1. Choose the Calculation Method

| Network Complexity | Recommended Method | Software Examples |

|---|---|---|

| Single pipeline | Joukowsky + Method of Characteristics (MOC) | Manual or simple Excel |

| Branched / looped network | Method of Characteristics (full transient) | Mandatory software |

| Any real network | Implicit or explicit MOC + surge protection | Bentley HAMMER, AFT Impulse, WANDA, Pipenet, Flowmaster, BOSfluids, KYpipe Surge, HYTRAN |

2. Collect Required Input Data

| Parameter | Typical Source / How to Get |

|---|---|

| Pipe geometry (length, diameter, thickness) | Design drawings |

| Pipe material & wall thickness | To calculate wave speed (a) |

| Fluid properties (density ρ, bulk modulus K) | Water at temperature → usually 1000 kg/m³, K = 2.2 GPa |

| Steady-state flow rates & pressures | Hydraulic model (EPANET, WaterGEMS, etc.) |

| Valve characteristics & closure time | Valve data sheet (Cv vs. stroke, closure law) |

| Pump data (inertia I, 4-quadrant curve) | Pump manufacturer |

| Air valves, surge tanks, check valves locations | Design documents |

| Elevation profile | Topographic survey |

3. Calculate the Wave Speed (a) – Critical Parameter

Joukowsky formula requires the celerity (speed of pressure wave):

a = √[ K / ρ × (1 + (K×D)/(E×e)) ]⁻¹

Where:

4. Maximum Theoretical Surge Pressure (Joukowsky)

For instantaneous full closure (the worst case):

ΔP = ρ × a × ΔV

ΔH = (a × ΔV) / g

Typical values:

5. Perform Full Transient Analysis (Software Steps)

Typical workflow in Bentley HAMMER / AFT Impulse / WANDA:

6. Quick Hand Calculation for Simple Pipeline (No Software)

Example: 1000 m steel pipe, DN300, 8 mm wall, flow 300 l/s, valve closes in 8 seconds.

7. Rules of Thumb for Design

| Situation | Maximum Acceptable Surge |

|---|---|

| Steel / DI pipe | ≤ 1.5 × PN rating |

| PVC / GRP | ≤ 1.3 × PN (more brittle) |

| Minimum pressure | > –0.5 bar gauge (avoid vapor pockets) |

| Valve closure time | > 10 × (2L/a) for longest pipe to keep surge low |

8. Recommended Software (2024–2025)

| Software | Best For | License Cost |

|---|---|---|

| Bentley HAMMER | Water distribution networks | High |

| AFT Impulse | Industrial/process piping | Medium |

| WANDA (Deltares) | Large transmission lines | Medium |

| KYpipe Surge | Very user-friendly, academic use | Low |

| Pipenet Transient | Firewater & complex oil/gas | High |

| BOSfluids | Detailed structural interaction | High |

Summary Checklist Before Final Design

If you have a specific network (even a small one), send me the layout, pipe data, and event, and I can walk you through the actual numbers or build a quick HAMMER/Impulse example.

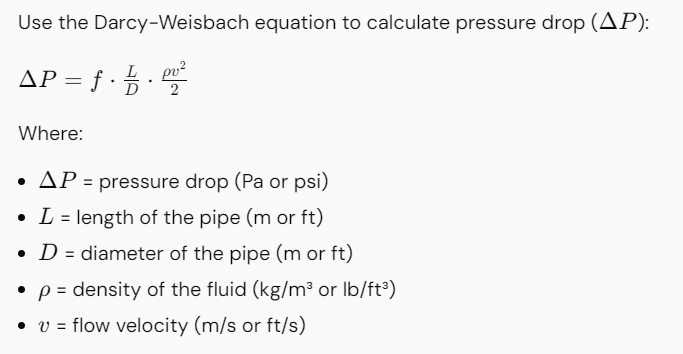

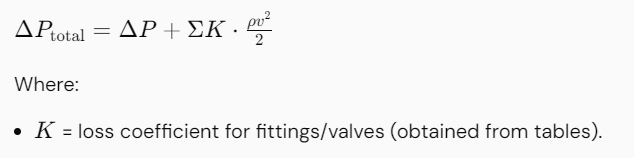

Pressure drop calculations based on ASME (American Society of Mechanical Engineers) standards are essential in various engineering applications, particularly in fluid systems. Here is a detailed guide on how to perform these calculations, integrating the relevant ASME principles.

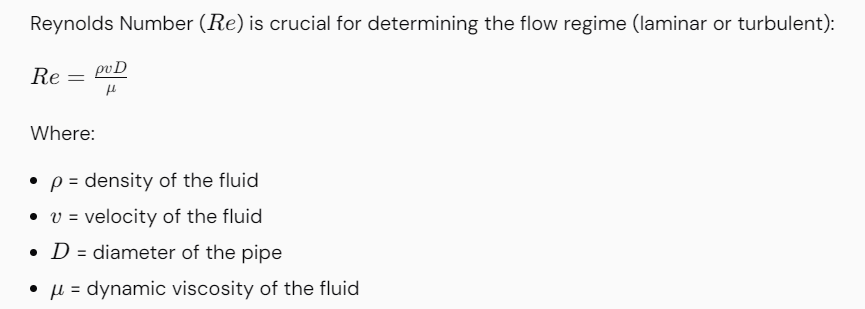

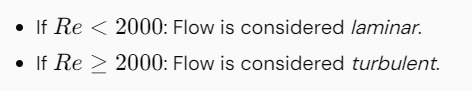

The Reynolds number describes the flow regime. \[ Re = \frac{ρvD}{μ} \] Where:

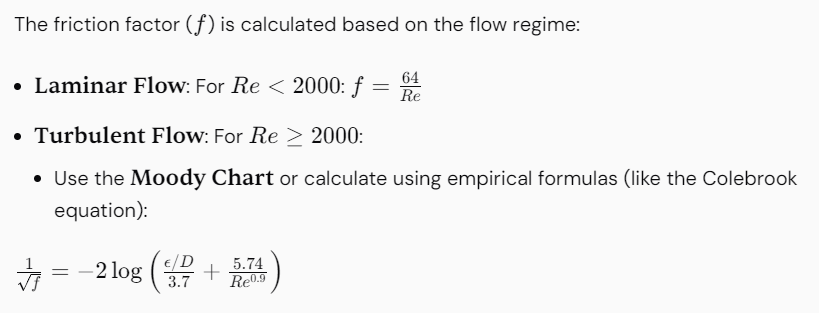

\[ v = \frac{Q}{A} = \frac{Q}{\frac{πD^2}{4}} \] For laminar flow: \[ f = \frac{64}{Re} \] For turbulent flow, use the Colebrook-White equation or Moody chart: \[ \frac{1}{\sqrt{f}} = -2 \log_{10} \left( \frac{ε/D}{3.7} + \frac{5.74}{Re^{0.9}} \right) \]

The Darcy-Weisbach equation is used: \[ ΔP_{friction} = f \cdot \frac{L}{D} \cdot \frac{ρv^2}{2} \] This is factored in with the equivalent length method or directly with loss coefficients: \[ ΔP_{fittings} = K \cdot \frac{ρv^2}{2} \] Combine all losses: \[ ΔP_{total} = ΔP_{friction} + ΔP_{fittings} \]

\[ A = \frac{π(0.1)^2}{4} = 0.00785 m^2 \] \[ v = \frac{0.01}{0.00785} ≈ 1.27 m/s \] \[ Re ≈ \frac{1000 \times 1.27 \times 0.1}{0.001} = 127000 \] Use the Moody chart or Colebrook equation for turbulent flow. Calculate pressure drop due to friction and fittings, then sum them.

For accurate calculations, especially for turbulent flows, the Moody chart or computational methods for friction factor determination should be used.

To illustrate pressure drop calculations based on ASME standards and display the equations as images, you’ll need to create the equations, convert them into images, and then embed them in your content. Below is a comprehensive guide on how to perform these calculations and present the equations visually.

Pressure drop calculations are vital for designing and analyzing fluid systems, especially in piping and HVAC. Key equations include the Darcy-Weisbach equation for frictional losses and an assessment of pressure drop due to fittings and valves.

To create images of these equations, you can use several tools or methods:

ΔP_{friction} = f \cdot \frac{L}{D} \cdot \frac{ρv^2}{2}, you can create an image.

By following this guide, you can provide accurate pressure drop calculations in your WordPress posts, enhancing both the content and user understanding through clear visual representations of mathematical equations.

Thermal relief valve should be set to pressure less than design pressure and higher than operating pressure because its design is small in size, so it will not discharge high flow

A DEVICE PREVENTING ROTATION ABOUT ONE OR MORE AXES DUE TO BENDING MOMENT OR TORSION. IN COMMON USAGE, A GUIDE NORMALLY PERMITS TRANSLATION ALONG THE PIPE AXIS BUT PREVENTS TRANSLATION PERPENDICULAR TO THE PIPE AXIS.

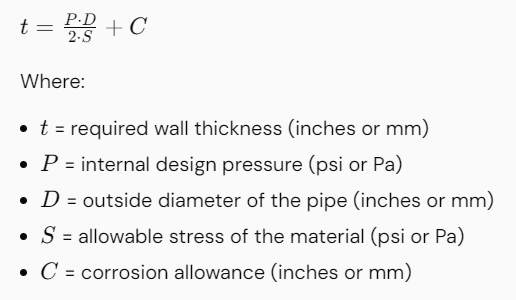

Calculating the wall thickness of a pipe is essential for ensuring the structural integrity and safety of piping systems, especially under internal pressure. The following steps outline how to calculate the pipe wall thickness based on ASME standards, particularly ASME B31.3 for process piping.

For an internally pressurized pipe, the minimum required thickness can be calculated using the following formula from ASME B31.3:

Note: For specified thickness definitions within ASME, you may also include a term for the minimum wall thickness. This can be specifically stated in different ASME sections.

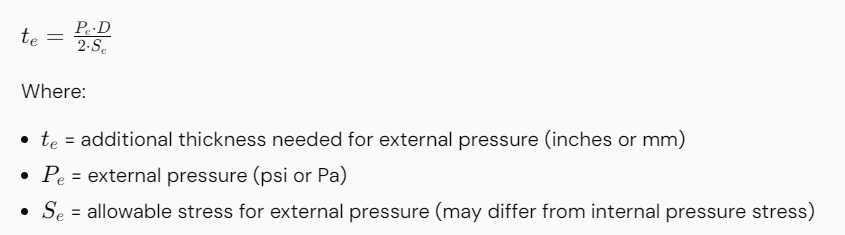

If the pipe is subject to external pressure, you must also consider the external pressure when calculating the wall thickness. Use the formula:

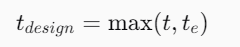

Combine thicknesses computed for internal and external pressures:

This equation helps in determining the final design thickness, accounting for both internal and external pressures.

Check if the calculated wall thickness meets or exceeds available standard pipe sizes and schedules (such as Schedule 40, 80). Pipe thicknesses defined by ASME pipe schedule can be found in ASME B36.10 and ASME B36.19.

Include any additional factors such as:

Adjust the thickness accordingly if required by safety factors or specific application standards.

Ensure the final design meets all relevant codes and standards (such as ASME B31.3, B31.1, etc.) and industry best practices. Perform peer reviews or checks per organizational procedures.

Calculating pipe wall thickness using ASME standards requires a comprehensive understanding of the operational conditions, material properties, and appropriate mathematical formulas. Consider the internal and external pressures, allowable stress, and corrosion allowances to ensure safety and compliance. This process is critical for the design, material selection, fabrication, and maintenance planning of piping systems. Always refer to the latest ASME codes and standards for the most accurate and safe design practices.

Calculating pressure drop in piping systems is a crucial aspect of engineering design. It helps in understanding the hydraulic performance of a pipeline and ensuring the system operates efficiently. The following steps outline the method to calculate pressure drop in a piping system based on ASME standards.

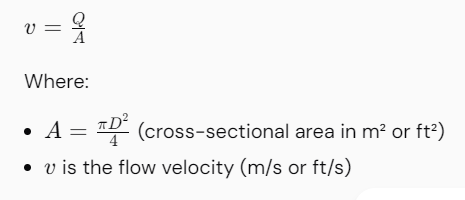

Using the flow rate, calculate the fluid velocity in the pipe:

Note:

Where:

Consider fittings, bends, valves, and other components in the piping system that contribute to pressure drop:

Add up the pressure drop from the straight pipe and all additional components to find the total pressure drop across the entire system.

The calculation of pressure drop in piping based on ASME standards involves understanding fluid properties, determining the flow regime, calculating friction factors, and applying the Darcy-Weisbach equation. Additional losses due to fittings and other components should also be considered. Always refer to relevant reference materials and standards for specific guidelines. This method will provide the necessary calculations to ensure efficient system design and operability.

Conducting a complex piping design analysis involves multiple steps that encompass planning, modeling, analysis, and optimization. Below is a comprehensive guide on how to perform such an analysis:

By following these steps, you can achieve an accurate and thorough complex piping design analysis, ensuring that the system is safe, efficient, and compliant with industry standards.

A simple piping design analysis involves several key steps to ensure the safety and efficiency of the system . Here’s a breakdown of how to perform one:

1. Define the System :

2. Determine Pipe Size and Schedule:

3. Calculate Pressure Drop:

4. Layout and Routing :

5. Model the System:

6. Support Design:

7. Stress Analysis :

8. Flexibility Analysis:

9. Evaluate the Results:

10. Optimize the Design:

* If the analysis reveals areas of concern, adjustments should be made to the design . Common solutions include:

* Adding or repositioning supports

* Incorporating expansion loops or joints

* Modifying the layout to reduce stresses

* Changing the material or wall thickness of the pipe

11. Verify Compliance:

* Ensure that the final design meets all relevant codes and standards .

Minimum corrosion allowance for stainless steels is 0.8 mm

Minimum corrosion allowance of 1.5 mm shall be provided for carbon steel material

The piping material selection process is a critical step in the design of any piping system . The goal is to choose materials that ensure the safe, reliable, and cost-effective transport of fluids while withstanding the operating conditions and environmental factors . Here’s a detailed explanation of the process:

By following these steps, engineers can select the most appropriate piping materials for a given application, ensuring the safety, reliability, and longevity of the piping system .

Stress Analysis

Data required for flexibility calculations

1. Code of Practice

2. Basic Material of Construction of Pipe

3. Ambient / Installation temperature

4. Number of Thermal Cases

5. Flexibility Temperature (See Note)

6. Design Pressure

7. Outside diameter of Pipe

8. Type of construction of pipe

9. Nominal Thickness of Pipe

10. Manufacturing tolerance

11. Corrosion allowance

12. Pipe Weight

13. Insulation Weight

14. Specific Gravity of Contents

15. Young’s Modulus at Ambient/Installation Temperature

16. Young’s Modulus at Flexibility Temperature

17. Thermal Expansion at Flexibility Temperature

18. Allowable stress at Ambient/ Installation temperature

19. Allowable stress at flexibility temperature

20. Bend radius and type of bend

21. Branch connection type

22. Weight of attachments – Valves and Specialties

23. Terminal movements with directions