Hot tapping is a technique used to create a connection to an existing pressurized pipe system without having to drain the system. Calculating the requirements for a hot tap involves several steps, including determining the size of the hot tap, assessing the pipe’s operating conditions, ensuring safety, and calculating any necessary factors like pressure and flow. Below is a systematic approach to hot tap calculations:

Steps for Hot Tap Calculations

1. Determine the Specifications of the Existing Piping System

- Pipe Size: Measure the nominal diameter of the pipe (e.g., inches or mm).

- Pipe Material: Identify the material of the pipe (e.g., carbon steel, stainless steel).

- Operating Pressure: Determine the internal pressure of the pipe when the hot tap will be performed.

- Operating Temperature: Measure the temperature during operation as it affects material strength.

2. Assess the Appurtenance

- Hot Tap Size: Decide on the size of the hot tap. This is usually based on the flow requirements for the new piping or branch connection.

3. Calculate Required Wall Thickness for the Effective Area

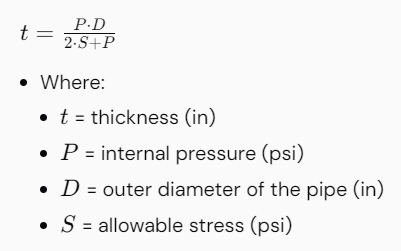

Using the ASME Boiler and Pressure Vessel Code, the wall thickness can be calculated based on the pipe diameter, material, and pressure parameters. Use formulas such as:

4. Select the Hot Tap Fitting

- Ensure the hot tap fitting is designed for the same service conditions (pressure, temperature) as the existing pipe.

5. Determine the Safe Working Conditions

- Review safety factors using established standards (like ASME, API).

- Calculate the Stress Intensity Factor (SIF) if applicable to ensure the existing pipe can tolerate the additional stresses from the hot tap without failures.

6. Calculate Flow Factors (if needed)

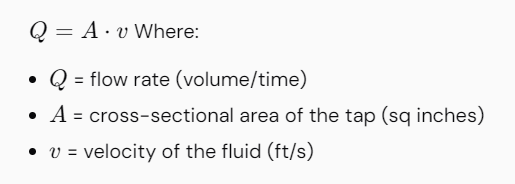

If there will be a flow through the new branch connection, perform calculations to ensure the desired flow rate is achieved. Use equations:

7. Safety Precautions and Verification

- Verify all calculations with industry standards.

- Conduct a risk assessment to ensure the operation will be safe.

- Ensure that the integrity of the existing system is maintained by performing strength evaluations.

8. Performing the Hot Tap Action

- Ensure proper equipment and personnel are ready.

- Implement procedures to execute the hot tap:

- Secure the worksite.

- Use the appropriate cutting equipment.

- Monitor pressure and flow during the operation.

9. Inspection and Testing Post-Hot Tap

- After the hot tap has been made, conduct inspections to confirm no leaks occur.

- Perform pressure testing if required to ensure the integrity of the new connection.

Summary

Hot tap calculations involve understanding the specifications of the pipe, calculating the required wall thickness, selecting the appropriate fittings, and ensuring safety considerations are met. The calculations help guarantee that the hot tap process is safe and effective, maintaining the integrity of the existing pipeline while allowing for new connections. Always refer to relevant codes and engineering practices for more specific guidelines tailored to your operation.