The flow is turbulent downstream the globe valve, so some inline items or equipment require minimum distance to ensure that flow became laminat

The flow is turbulent downstream the globe valve, so some inline items or equipment require minimum distance to ensure that flow became laminat

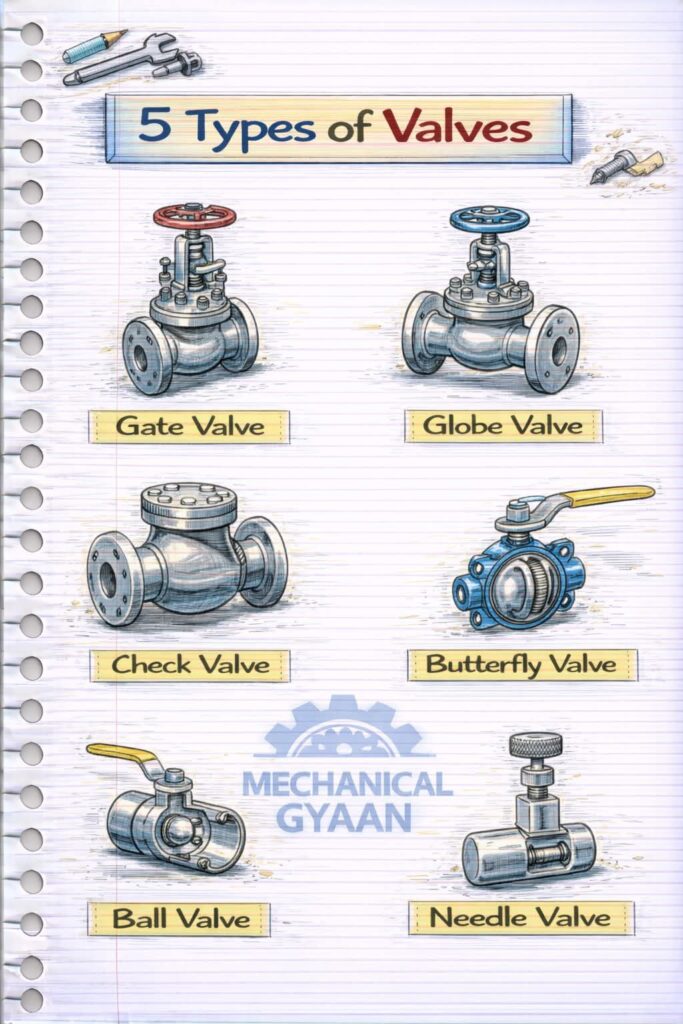

Valves that are not classified as full bore typically have a smaller internal diameter than the nominal diameter of the pipe they are connected to, which may result in restrictions on flow. Here are common types of reduced bore and non-full bore valves:

Understanding the type of valve and its design is crucial for ensuring the performance meets the specific flow requirements of an application. Reduced bore valves, while advantageous in some cases, may lead to increased pressure drops and reduced flow rates compared to full bore options.

Ball valves are quarter-turn valves that use a hollow, perforated, and pivoting ball to control fluid flow . They are known for providing tight shutoff, durability, and ease of operation . Here are the main types of ball valves and their uses:

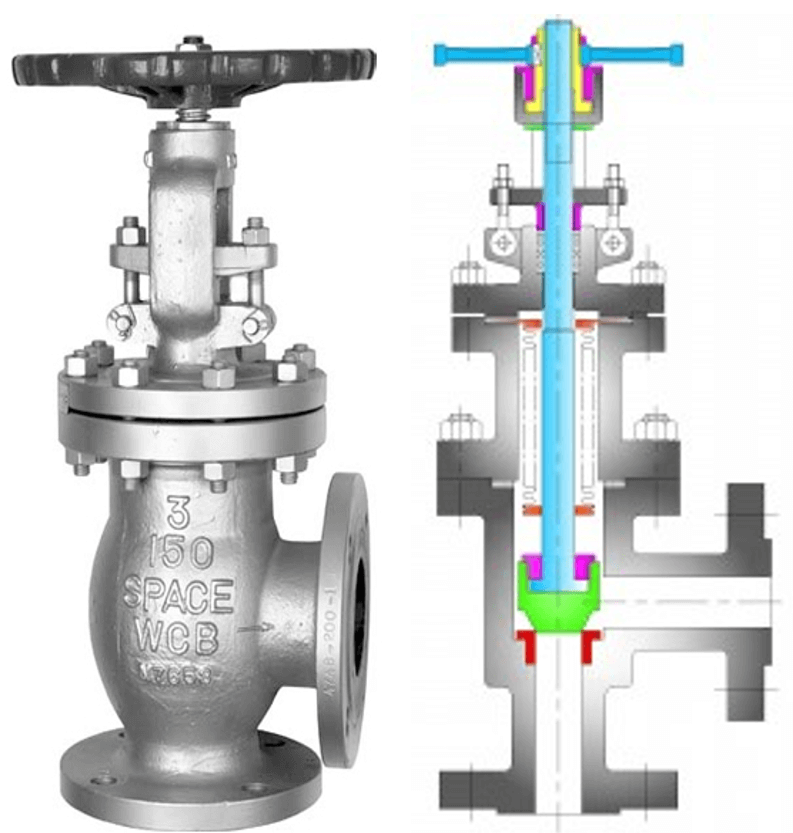

Gate valves are classified based on the type of disc, body-bonnet joint, and stem movement . Here’s a breakdown:

I. Based on Disc Type:

II. Based on Body-Bonnet Joint:

III. Based on Stem Movement:

Additional Types:

Screwed bonnet: This is the simplest design available and it is used for inexpensive valves.

Bolted-bonnet: This is the most popular design and used in a large number of globe valves. This requires a gasket to seal the joint between the body and bonnet.

Welded-Bonnet: This is a popular design where disassembly is not required. They are lighter in weight than their bolted-bonnet counterparts.

Pressure-Seal Bonnet: This type is used extensively for high-pressure high-temperature applications. The higher the body cavity pressure, the greater the force on the

gasket in a pressure -seal valve.

Application of Globe valve

Globe Valves are used in the systems where flow control is required and leak tightness is also important.

It used in high-point vents and low-point drains when leak tightness and safety are major concerns. Otherwise, you can use a gate valve for drain and vent.

It can be used in Feed-water, chemical, air, lube oil and almost all services where pressure drop is not an issue

This valve is also used as an automatic control valve, but in that case, the stem of the valve is a smooth stem rather than threaded and is opened and closed by lifting action of an actuator assembly.

Advantages

Better shut off as compared to gate valve

Good for frequent operation as no fear of wear of seat and disk

Easy to repair, as seat and disk can be accessed from the valve top

Fast operation compares to gate valve due to shorter stroke length

Usually operated by an automatic actuator

Disadvantages

High head loss from two or more right-angle turns of flowing fluid within the valve body.

Obstructions and discontinuities in the flow path lead to a high head loss.

In a large high-pressure line, pulsations and impacts can damage internal trim parts.

A large valve require considerable power to open and create noise while in operation.

It is heavier than other valves of the same pressure rating.

Costlier compared to the gate valve

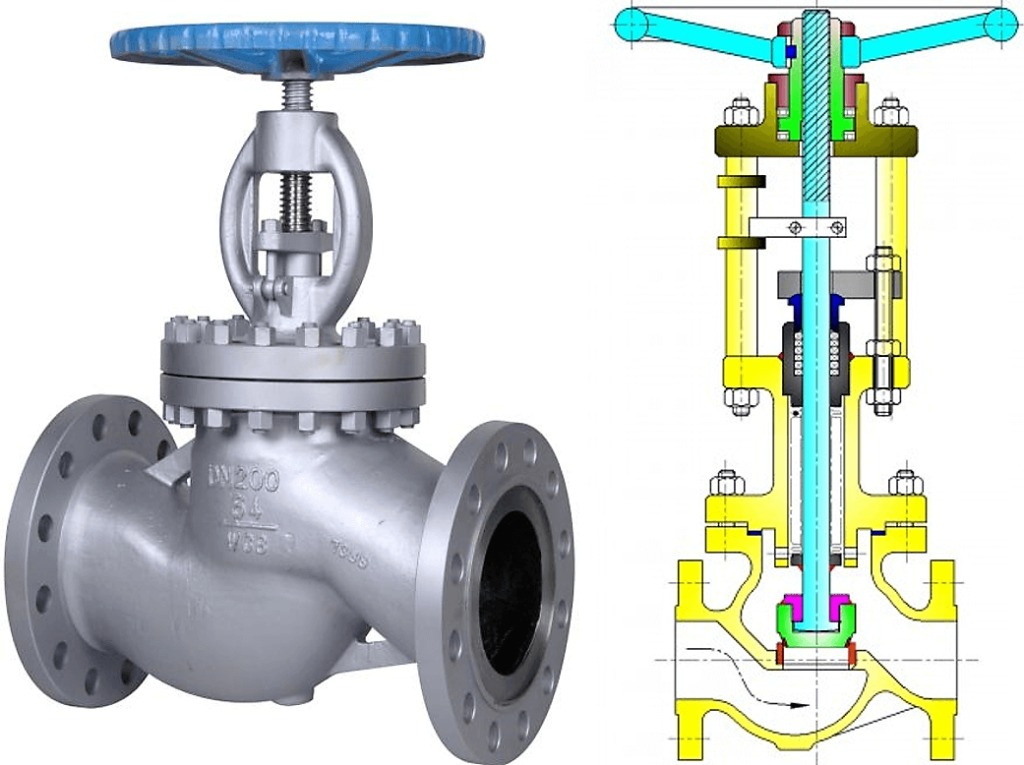

Depending on the type of body there are three types of globe valves;

The simplest design and most common type is a Z-body. The Z-shaped partition inside the globular body contains the seat. The horizontal seating arrangement of the

seat allows the stem and disk to travel at a perpendicular to the pipe axis resulting in a very high-pressure loss.

The valve seat is easily accessible through the bonnet which is attached to a large opening at the top of the valve body. Stem passes through the bonnet like a gate

valve.

This design simplifies manufacturing, installation, and repair. This type of valve is used where pressure drop is not a concern and throttling is required.

The Y-type design is a solution for the high-pressure drop problem in Z-type valves. In this type, seat and stem are angled at approximately 45° to the pipe axis. Y-body valves are used in high pressure and other critical services where pressure drop is concerned.

Angle globe valve turns the flow direction by 90 degrees without using an elbow and one extra pipe weld. Disk open against the flow. This type of globe valve can be

used in the fluctuating flow condition also, as they are capable of handling the slugging effect.

if the vessel is protected by multiple relief devices, then one relief device must be set no higher than the MAWP but the others can be set as high as 105% of the MAWP.

Relief Valves

– The required relief area for two-phase flow is typically two to ten times the area for single-phase flow.

– For spring-operated relief valves, small amounts of leakage start to occur at 92–95% of the set pressure.

– A relief devices over-pressure is the pressure increase over its set pressure, usually expressed as a percentage of the set pressure. Pop-acting relief valves do not immediately open completely (to 100% lift). Sufficient over pressure is necessary to achieve full lift.

– if the vessel is protected by multiple relief devices, then one relief device must be set no higher than the MAWP but the others can be set as high as 105% of the MAWP.

On the long term negative effects of rusting on steel valves will reduce the structural integrity of the valve, since rust has different physical characteristics than steel

Valve selection according to (pressure drop, seat leakage, fluid properties, system leakage, actuation requirements, initial cost & maintenance)