A DEVICE WHICH PREVENTS TRANSLATIONAL MOVEMENT IN ONE DIRECTION ALONG EACH OF TWO AXES. A “TWO-AXIS DOUBLE-ACTING STOP” PREVENTS TRANSLATIONAL MOVEMENT IN THE PLANE OF THE AXES WHILE ALLOWING SUCH MOVEMENT NORMAL TO THE PLANE.

POST WELD HEAT TREATMENT USED TO RELIVE THE TRAPPED ELASTIC STRESS

A PIPE ATTACHMENT DETAIL IN WHICH A PIPE IS INSERTED INTO A RECESSED AREA OF A FITTING, AND THEN FILLET WELDED BETWEEN ITS OUTSIDE DIAMETER AND THE FITTING END.

A NONMETALLIC BLANKET THAT FORMS ON THE TOP OF THE MOLTEN WELD METAL. IT HELPS TO CONTROL THE TEMPERATURE, THE COOLING RATE, AND ASSISTS IN PREVENTING AND REMOVING IMPURITIES FROM THE WELD METAL.

THE USE OF RADIANT ENERGY IN THE FORM OF NEUTRONS, X-RAYS OR GAMMA RAYS FOR THE NONDESTRUCTIVE EXAMINATION OF OPAQUE OBJECTS. IT PRODUCES GRAPHICAL RECORDS ON SENSITIZED FILMS WHICH INDICATE THE COMPARATIVE SOUNDNESS OF THE OBJECT BEING TESTED.

USE OF AN ELECTRIC ARC GENERATED AT THE TIP OF A WELDING ELECTRODE TO CUT METAL.

Based on ASME (American Society of Mechanical Engineers) standards which involves outlining the necessary steps to ensure that welding is performed safely and effectively while maintaining high quality and integrity. Below is a comprehensive general welding procedure that can be adapted for various applications.

General Welding Procedure Based on ASME

1. Purpose and Scope

- Purpose: Define the goals of the welding process, including structural integrity, safety, and performance requirements.

- Scope: Specify the materials, types of joints, and applications covered by the procedure, such as carbon steel, stainless steel, and alloy steel welding.

2. References

- ASME Section IX: Welding and Brazing Qualifications

- American Welding Society (AWS) specifications and standards

- Material specifications (ASME B31.3, ASME B31.1, etc.)

- Manufacturer’s data sheets for filler materials

3. Welding Processes

Specify the welding processes to be used, such as:

- SMAW: Shielded Metal Arc Welding (Stick Welding)

- GMAW: Gas Metal Arc Welding (MIG Welding)

- FCAW: Flux-Cored Arc Welding

- TIG: Gas Tungsten Arc Welding

- SAW: Submerged Arc Welding

4. Welding Materials

- Base Metals: Identify the materials to be welded, including their specifications (e.g., ASTM).

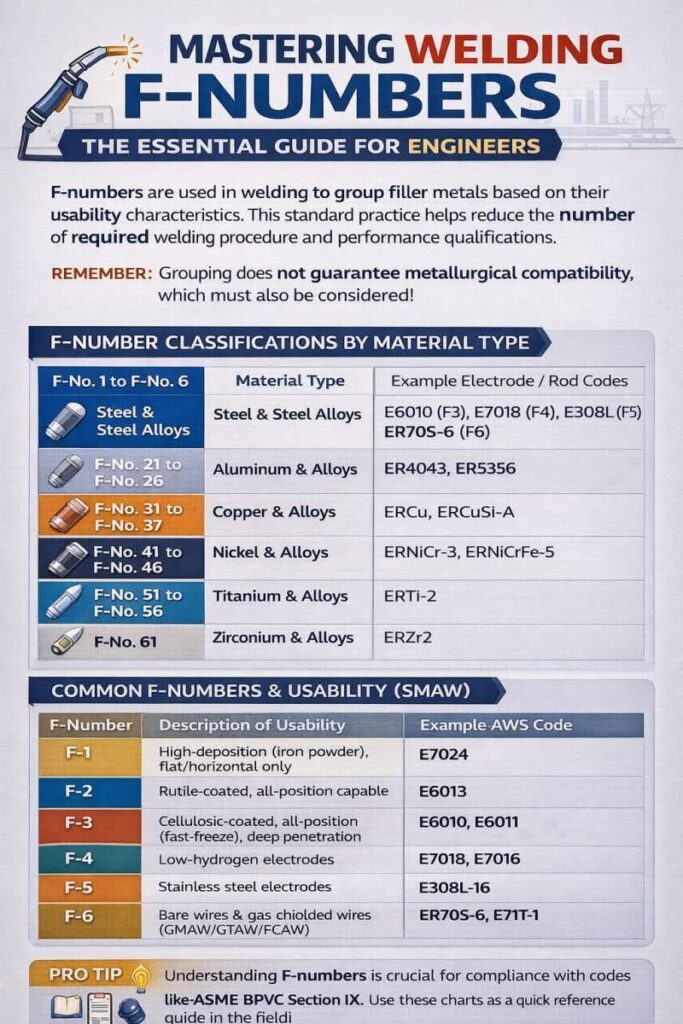

- Filler Materials: Specify the type and classification of filler metals per AWS/ASME standards.

- Shielding Gases: Identify the type of shielding gas used for processes like GMAW or TIG welding (e.g., Argon, CO2, Helium).

5. Welding Joint Design

- Outline the joint configurations, including:

- Butt Joints

- Fillet Joints

- Edge Joints

- Define the joint design based on the required strength and service conditions, ensuring it is compliant with relevant ASME codes.

6. Preparation of Base Metals

- Cleaning: Remove contaminants such as rust, oil, dust, and other impurities from the surfaces to be welded.

- Fit-Up: Ensure proper fit-up of the joint with tolerances as specified in the applicable standards.

- Preheating: If necessary, preheat the base materials to reduce the risk of cracking based on material type and thickness.

7. Welding Parameters

Specify the following parameters:

- Voltage (V): Set appropriate arc voltage for the welding process.

- Current (I): Set the welding current according to the process and joint thickness.

- Travel Speed: Determine the appropriate welding speed to ensure proper bead appearance and penetration.

- Heat Input: Calculate or control the heat input to minimize distortion and prevent material degradation.

8. Welding Technique

Provide details on the technique to be used, including:

- Electrode Angle: Specify the angle of the electrode or torch relative to the workpiece.

- Weaving: Include details on weaving patterns for different joint configurations (if applicable).

- Pass Sequence: Define the sequence of weld passes (e.g., root pass, fill passes, final cap pass).

9. Inspection and Testing

- Visual Inspection: Conduct a visual examination of the welds to check for defects such as undercuts, porosity, and cracks.

- Non-Destructive Testing (NDT): Specify NDT methods (e.g., RT, UT, MT, PT) to be implemented based on service requirements to ensure weld integrity.

- Destructive Testing: Outline any requirements for tensile, impact, or bend tests if necessary according to applicable codes.

10. Post-Weld Heat Treatment (PWHT)

If required by the material or design specifications, specify post-weld heat treatment details, including:

- Temperature and duration

- Cooling rate and method

11. Safety Considerations

- Implement safety measures throughout the welding process, including:

- Personal Protective Equipment (PPE) such as helmets, gloves, and protective clothing.

- Ventilation to avoid exposure to harmful fumes.

- Equipment safety checks before operation.

12. Documentation and Records

- Maintain records of:

- Welder qualifications (per ASME Section IX)

- Welding procedure specifications (WPS)

- Inspection and testing results

- Material and filler metal certifications

13. Training and Qualification

- Ensure that personnel performing the welding are trained and qualified in the applicable welding processes, techniques, and safety practices.

Conclusion

This general welding procedure based on ASME provides a structured approach to welding operations, covering all necessary steps from planning and material selection to final inspections and documentation. Adhering to these guidelines facilitates quality assurance and compliance with industry standards, ensuring that welded structures meet performance and safety requirements. Always refer to current codes and standards for specific applications.

(PQR)procedure qualifications record: suggested procedure of welding which reflected in WPS if accepted